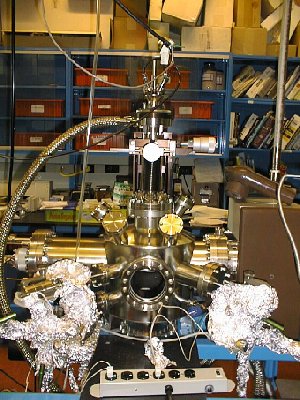

The use of ports in the system design has been optimized by mounting on one 8-in. port a 120 l/s ion pump (Perkin Elmer 2070122), a titanium sublimation pump (TSP) (Perkin Elmer 2140411), and acryoshroud (Perkin Elmer 1001341). According to the manufacturer, the combined pumping speed of this system is over 1000 l/s for H2O.

The vertical 360 l/s air-cooled turbomolecular pump (Leybold TMP360V) is separated from the UHV chamber by an 8-in. stainless steel electro-pneumatic gate valve (MDC GV-8000M-P), incorporating a metal sealed bonnet and a Viton sealed gate. A dual stage 11.6 cfm (5.5 l/s) rotary vane pump (Leybold D16B) removes evacuated gases from the turbomolecular pump's outlet. Typically, an extra turbomolecular or diffusion pump is incorporated between the turbomolecular and rotary vane pumps. In conjunction with the use of the TSP, the chamber described herein can operate in the 10-11 Torr pressure range with the turbomolecular pump backed only by a rotary vane pump.

In addition to evacuating the UHV chamber, the turbomolecular pump is used to evacuate the inner stage of the two-stage differentially pumped rotary feedthrough (DPRF) (McAllister Technical Services) and the gas-handling system through an additional 2.75-in. port on the gate valve. When the turbomolecular pump is pumping on the UHV chamber, the gas-handling system and the DPRF are isolated from the turbomolecular pump with a 1.5-in. stainless steel in-line bellows valve (MDC 322018) with a Viton seal. Although turbomolecular pumps have been previously employed for multiple uses, the special gate valve incorporated in our design maximizes the effective pumping speed of the turbomolecular pump when evacuating the UHV chamber.

A convectron (Granville-Phillips model 275) is mounted directly on the UHV chamber to measure elevated pressures (10-4 - 1000 Torr).