The molybdenum (Mo) single crystal is mounted on the stainless steel/copper sample holder which provides for liquid nitrogen cooling down to 100 K and heating via both radiation and electron bombardment up to 2300 K.

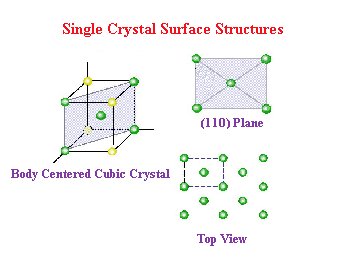

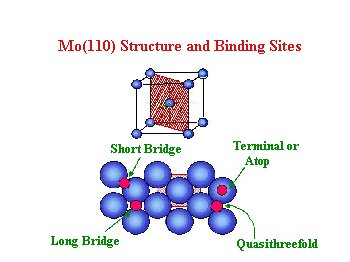

The Mo(110) single crystal (8mm diameter) used in the experiments was obtained from Crystal Preparation Laboratory. The (110) after the Mo refers to the Miller indices of the crystal plane along which the crystal is cut. The Mo(110) crystal is cleaned in situ by dosing oxygen (2×10-9 torr) onto the surface at 1300 K for 5 minutes to remove carbon buildup. Oxygen reacts with carbon on the crystal surface, forming carbon monoxide. The CO formed on the surface desorbs immediately since the crystal is already at a temperature above that for CO desorption. Flashing the crystal to 2200 K after oxygen dosing removes residual oxygen, providing a clean surface.

The cleanliness of the surface is quantified using TPRS after dosing oxygen at 85 K. Desorption of CO from the surface is monitored by the mass spectrometer. The CO saturation coverage is assumed to be 1 ML. The carbon coverage after repeated oxygen cleaning cycles is determined to be less than 0.01 ML.