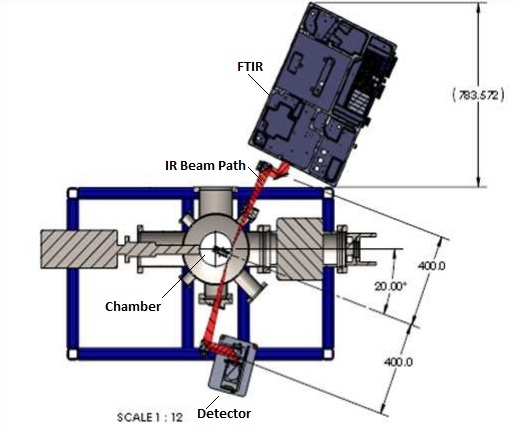

Infrared Reflection Absorption Spectroscopy (IRAS) is used to identify photolysis/radiolysis products. In contrast to temperature programmed desorption, IRAS does not require thermal processing prior to product detection. A TENSORTM 27 FTIR spectrometer from Bruker Optics was coupled to our ultrahigh vacuum (UHV) system and made operational for IRAS experiments. Maximum absorbance occurs when the beam is near grazing incidence, ~80⁰ to the surface normal. IR light is reflected onto the substrate using external gold-coated plane and parabolic mirrors. The size of the beam spot at the crystal is calculated to be 20×115 mm for an 80⁰ angle of incidence. Therefore the crystal, being about one centimeter in diameter, is exposed to less than 5% of the incident IR light.

During each IRAS measurement, optical alignment is optimized by adjusting the x and y positions of the crystal stage by using precision micrometers. The crystal’s θ coordinate is optimized by observing the amplitude of IR signal at the detector. Image dipole effects caused by the metal surface mirroring dipoles in the adsorbed species cancels the ability of the s-polarized component of light to excite a dipole along the metal surface.